How To Tell Good Forging Factories – 5 Tricks For Newbies

On October 13, 2023 by rimrockForging is a manufacturing process in which metal is shaped using localized compressive forces. The quality and reliability of products manufactured through forging are highly dependent on the capability and proficiency of the forging factory. If you’re new to the industry and looking to partner with a reliable forging factory, it might seem overwhelming. Fortunately,

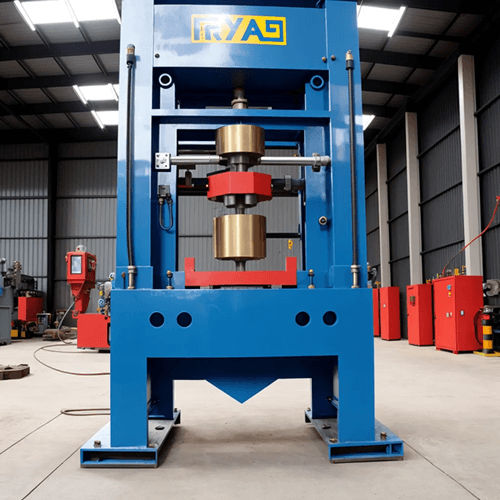

The Best 12 Ton Hydraulic Press For You – 5 Features

On October 12, 2023 by rimrockThe world of hydraulic presses is vast and varied, and with a myriad of options available, it can be overwhelming to find the perfect fit for your requirements. One of the popular choices for both hobbyists and professionals is the 12-ton hydraulic press. It offers a balance of power and versatility without overwhelming the user.

Industries Growing The Cold Forging Of Aluminum

On October 10, 2023 by rimrockAluminum, owing to its lightweight, high conductivity, and corrosion resistance, has found use in myriad applications across various industries. One method that has revolutionized the usage of aluminum in various sectors is cold forging. Here, we’ll look at 5 industries that are seeing significant growth thanks to cold forging aluminum. Automotive Industry Fuel Efficiency: As

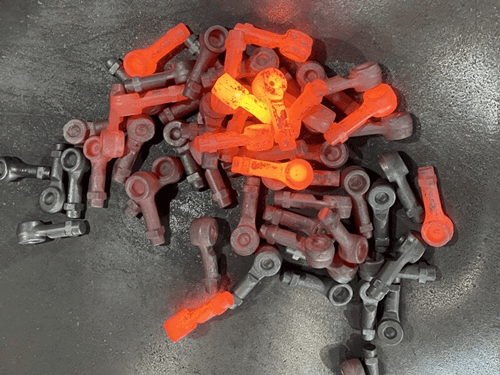

This Is The Kind Of Forging Parts Manufacturer You Should Work With

On October 4, 2023 by rimrockForging is a complex and intricate process that requires a combination of expertise, precision, and advanced machinery. Whether you’re in the automotive, aerospace, or any industry that relies heavily on metal parts, partnering with the right forging parts manufacturer is crucial. Here are the 4 traits to look for in a good forging parts manufacturer:

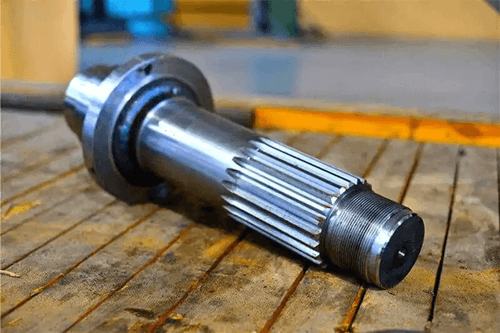

Why The Number Forging Gears Is Growing Rapidly

On September 8, 2023 by rimrockIn recent years, the manufacturing industry has witnessed an exponential growth in the popularity of forging gears. This can be attributed to a multitude of factors that have changed the traditional perspectives on gear production. Here, we explore five key reasons why the popularity of forging gears has been growing rapidly. Superior Durability The forging

Cold Forge Vs Hot Forge: Which One To Pick

On September 5, 2023 by rimrockForging is a metalworking process used to shape metal parts by applying compressive forces. Two popular methods employed in this domain are cold forge and hot forge. While both techniques yield strong and durable metal components, they differ significantly in terms of temperature, workability, and the properties of the final products. In this article, we

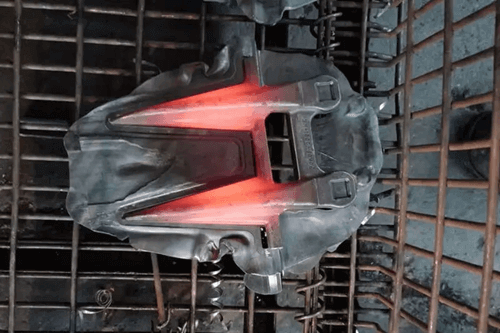

Why Hot Die Forging? Here Are 5 Advantages You Should Know

On August 7, 2023 by rimrockHot die forging involves heating a metal workpiece to high temperatures and then using a hammer or a press to shape it into a predefined design. The heated metal, softened by the high temperatures, can be manipulated easily, reducing the force needed for deformation. This article will highlight five key advantages of hot die forging

The Cold Forging Process – 5 Important Things Manufacturers Always Considers

On July 17, 2023 by rimrockCold forging is a highly efficient and widely used manufacturing process that involves shaping metal parts using compressive forces at room temperature. Manufacturers across various industries rely on cold forging to produce high-quality components with exceptional strength, precision, and cost-effectiveness. However, to ensure successful cold forging operations, manufacturers must carefully consider several crucial factors. In

This Is What Buyers Miss When Picking Forging Parts Manufacturers

On June 13, 2023 by rimrockWhen selecting forging parts manufacturers, a lot of buyers make the mistake of rushing for the enticing without checking how good these deals are. In fact, most of the newbies are attracted by the deals that promise to save them huge sums of money if they buy from them. Most end up getting scammed. There

Cold Extrusion Process: Best Guide 2023

On June 7, 2023 by rimrockExtrusion technology has been for a long time, especially in the metal manufacturing industry. The forming process includes forcing a workpiece through a die to form the desired. The process is easy to work with as it does not require a lot of machinery and equipment to work with. But what does the cold extrusion